Wheat Flour Mill Plant

Price 1221162.00 INR/ Unit

MOQ : 1 Unit

Wheat Flour Mill Plant Specification

- Product Type

- flour mill plant

- Material

- Galvanized Steel

- Type

- Flour Grinding Machine, Grain Processing Equipment

- Capacity

- 250 kg , 500 kg , 1000 kg ,2000 kg ,4000 kg Kg/hr

- Computerized

- No

- Automatic

- Yes

- Control System

- Manual

- Cleaning System

- Destoner

- Voltage

- 440 Volt (v)

- Raw Material

- Wheat

- Feature

- Low Noice, Compact Structure, High Efficiency, Lower Energy Consumption

- Color

- White

- Warranty

- 1 year

Wheat Flour Mill Plant Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cheque, Cash Advance (CA), Cash on Delivery (COD), Cash Against Delivery (CAD), Cash in Advance (CID)

- Supply Ability

- 5 Units Per Week

- Delivery Time

- 15 Days

- Packaging Details

- Plastic packaging

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

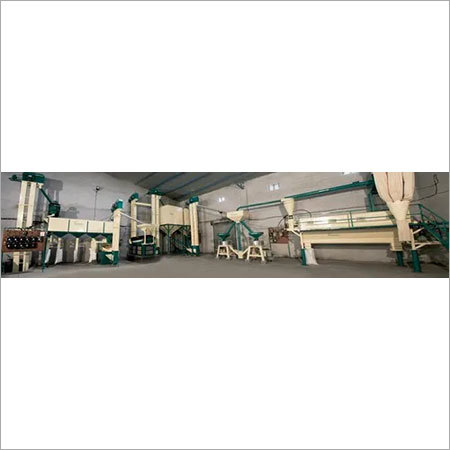

About Wheat Flour Mill Plant

We have been engaged in the production of Wheat Flour Mill Plant that also acts as flour grinding machine. This grain processing equipment works as an ideal separator which removes impurities and dust from wheat and extracts the pure item that is edible and hygienic by all means. The mill plant comes with easy installation process and is swift in terms of operation. In addition, the flour processing machine works with low noise and is highly efficient in terms of withstanding high capacity load and delivering the end-product in a short span of time. The Wheat Flour Mill Plant manufactured by us is available in various dimensions to meet the diverse need of clients. We also offer the plants at competitive pricing.

Efficient Wheat Flour Processing

Designed for industrial and commercial applications, this flour mill plant offers a streamlined solution for processing wheat into high-quality flour. Its automatic functionality, combined with manual controls, allows for reliable production with reduced supervision. The integrated cleaning system ensures that only the best grains are processed, promoting superior flour quality and hygiene.

Versatile Production Capacity

The plant offers multiple capacity options250 kg, 500 kg, 1000 kg, 2000 kg, and 4000 kg per hourmaking it suitable for both small and large-scale operations. Its robust construction from galvanized steel ensures longevity even in demanding environments, while its compact structure saves valuable production space.

FAQs of Wheat Flour Mill Plant:

Q: How does the cleaning system work in this wheat flour mill plant?

A: The plant features a dual cleaning system consisting of a separator and a destoner. The separator removes larger debris, while the destoner eliminates stones and other heavier impurities from wheat before grinding, ensuring clean and safe flour production.Q: What is the voltage and material specification of the mill plant?

A: The wheat flour mill plant operates at 440 Volt and is constructed from durable galvanized steel, offering excellent longevity and resistance to corrosion.Q: When is it suitable to use different processing capacities?

A: The plant is available in 250 kg, 500 kg, 1000 kg, 2000 kg, and 4000 kg per hour capacities. Lower capacities are ideal for smaller businesses or startups, while higher capacities suit large-scale commercial operations or continuous production environments.Q: Where is this flour mill plant commonly used?

A: This machine is widely used by dealers, exporters, manufacturers, retailers, and wholesalers across India for the production of wheat flour in both rural and urban settings.Q: What benefits does the automatic system offer with manual control?

A: Although the system operates automatically to streamline the grinding process, manual controls provide flexibility and adaptability, enabling easy workflow adjustments and maintenance interventions as needed.Q: How energy-efficient and noise-reducing is the plant?

A: The plant is designed with lower energy consumption features and a low-noise operational profile, supporting sustainable production and a comfortable working environment.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Flour Mill Plants Category

Atta Plant

Price 1411000 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : No

Control System : Manual

Capacity : 250 Kg, 500 Kg, 1000 kg, 2000 kg . Kg/hr

Weight (kg) : 7 Tonne

Industrial atta chakki plant

Price 1071000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : No

Control System : Manual

Capacity : 2002000 Kg/hr

Weight (kg) : 45 Tonne

Atta Chakki Plant

Price 688000 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : No

Control System : Manual

Capacity : 200,500,1000,2000 Kg/hr

Weight (kg) : 45 Tonne

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS